Last Thursday I did a little shopping at Harbor Freight and picked up the three shelf service cart, the 1,000 lb engine stand, another oil drain pan, some flarenut wrenches, and some other assorted things.

Last night, I crawled underneath to take a look at everything. From my untrained eye, there is no unexpected or hidden damage to the suspension and drivetrain components. There’s some rust here or there, but I think that a good wire brushing, rust conversion, and POR-15 (or equivalent) treatment will mitigate any rusting.

I looked at the axles, the steering rack, the control arms, the engine mounts, etc. The right CV axle boot has a tear in it, so that axle will be replaced. There’s a mystery grease on the right side of the transmission which has me concerned as well, but I think it might be grease slung out of the axle boot.

Even the exhaust system does not look like it would be impossible to take apart. The “spring bolts” that hold the down pipe to the flange that heads aft looks like with enough PBlaster, I’ll be able to take them apart.

The only concern I have is on the unibody structure. There are two areas that seem to be cut away and rusty, on either side of the car, that worry me.

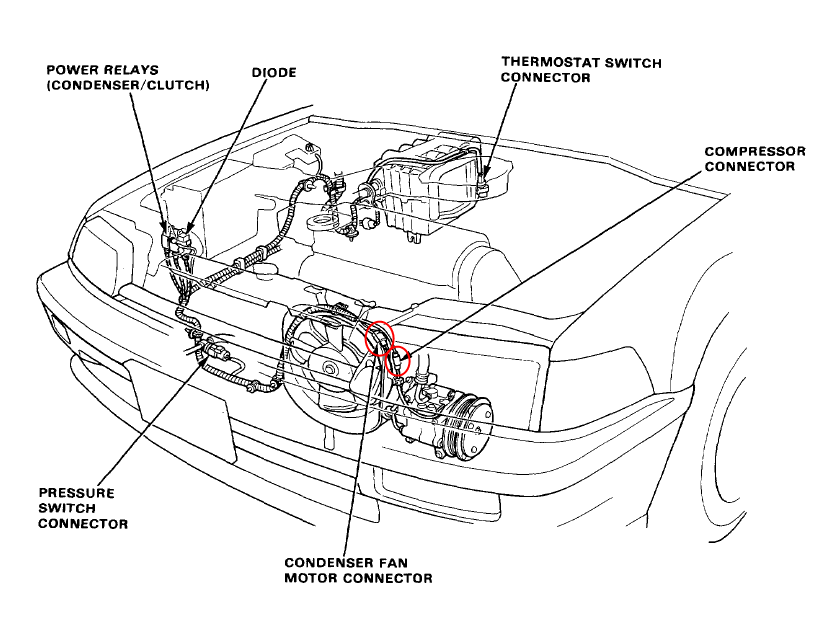

Since I’m pulling the engine, I decided to move along and follow the shop manual procedure, but also pull the radiator out while I’m at it. If I’m rebuilding or replacing the engine, it would be prudent to look at, clean up, and mitigate rust on the entire engine bay and all of its parts.

I removed the plastic splash shield attached to the underside of the front bumper structure and the front crossmember. It’s in two pieces, and it is clear that some repairs/replacement fasteners were used here. There’s also a fair amount of abrasion damage to this area, like the front of the car impacted a pile of gravel. The seller told me this was due to an incompetent towing job. As I did this, a large quantity of dirt and gravel rained down on my face, even though I tried to prevent that from happening. Once the shield was off, I had access to the coolant drain plug and other parts. Everything looks to be pretty much in order, with some rusting here and there.

The transmission draining went fine. I used my 3/8″ socket wrench and a piece of conduit as a torque amplifier. The fluid looked clear and normal.

Since this engine has serious internal failure, I inspected the oil pan and see two places where parts punched a hole in it. I did not see any damage to the block, but I won’t know for sure until it’s out of the car and on the stand.

There was a good quantity of engine oil that drained out when I took the bolt off, and it was black as midnight. It smelled really bad too.

Finally, I drained the coolant. I removed the petcock from the bottom of the radiator, and coolant began to dribble out. I took of the radiator cap and it started gushing out, so I modulated the flow by keeping the cap on partially screwed in.

What I see as a positive is that the coolant drained out clear and greenish yellow. No “chocolate milk” syndrome, so I’m pretty confident that the coolant and oil was not mixing. It can be reasonably asserted the the engine isn’t failed so that the separation between coolant and oil passages are not breached.

So Saturday night ended with the vital fluids (except for the brakes) drained out of the car. Today I will remove hoses/electrical connections, and get the radiator out. Time permitting, I’ll move forward from there.